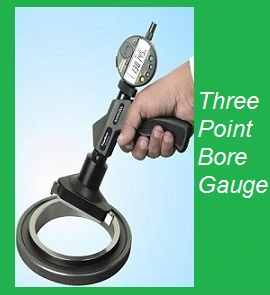

3 Point Bore Gauge

A 3-point bore gauge is a precision instrument used for measuring the internal diameter of holes or bores with high accuracy. It's particularly useful in manufacturing and machining contexts where tight tolerances are required.Here s a brief overview of how it works and its features:

Components:

1. Main Body: The central part of the gauge, which holds the measuring elements.

2. Measuring Spindles: These are the three points that make contact with the inner surface of the bore. They are usually spring-loaded to accommodate slight variations in bore size.

3. Dial Indicator or Digital Readout:Measures the distance between the spindles and provides a reading of the bore's diameter.

4. Adjustment Mechanism: Allows for fine-tuning and zeroing of the gauge before measurement.

How It Works:

1. Insertion: The gauge is inserted into the bore.

2. Contact:The three spindles make contact with the inner surface of the bore. They are arranged in a triangular pattern to provide a stable and accurate measurement.

3. Measurement:The gauge is adjusted until the spindles make firm contact with the bore's surface. The gauge then measures the distance between the spindles, which corresponds to the bore's diameter.

4. Reading:The dial indicator or digital readout provides a precise measurement of the bores diameter.

True cal Calibration System for 3 Point Bore Gauges

True Cal Calibration System:True-Cal Is An Innovative Solution To The Problems Presented By The Accurate Calibration Of 3 Point Bore Gauge Micrometers. Any Micrometer (From 16-200mm) Can Be Calibrated On A Single Unit, And The True-Cal Method Dispenses With The Need For Large Numbers Of Settings Rings And Provides More Comprehensive Results.

Bore Gauge Our range of products include Deep Bore Gauge,Deep Hole Bore Gauges,Thread Bore Measurement,Thread Bore Gauge Machine,O Ring Groove Bore Gauge, Ball Screw Thread Bore Gauge,Slot Bore Gauge,Triga Bore Gauge,Special Bore Measurement,Ball Screw Thread Bore Measurement,Taper Bore Dial Measurement Gauge,True Bore Gauge,Spherical Bore Diameter Measurement Gauge,Spline Bore Gauge,Borematic Type True Bore Gauge,Standard Bore Gauges,Inside Bore Gauge,Plug Bore Gauge,Bore Gauge Heads and Electronic Bore Gauge.

Bore Gauge

A bore gauge is a precision tool used to measure the internal diameter of a hole or cylinder. It's commonly used in machining and engineering to ensure that holes are manufactured to the correct dimensions and tolerances.Bore gauges come in various types, such as dial bore gauges and digital bore gauges. They typically consist of a micrometer head or dial indicator attached to a set of expandable measuring tips. The gauge is inserted into the hole, and the internal diameter is measured by adjusting the tips until they make contact with the sides of the hole. The measurement is then read from the dial or digital display.If you're working on a project that requires precise measurements of internal diameters, a bore gauge is a crucial tool to have.

Type of Bore Gauge

A bore gauge is a measuring instrument used to measure the diameter of holes, bores, or cylinders accurately. There are several types of bore gauges commonly used: 1. Telescoping Gauge 2. Inside Micrometer 3. Three Point Bore Gauge Internal Micrometer 4. Bore Gauge Setting Ring 5. Electronic Bore Gauge Each type of bore gauge has its specific applications and advantages depending on the level of precision required and the type of bore being measured.

Type of Bore Gauge

A bore gauge is a measuring instrument used to measure the diameter of holes, bores, or cylinders accurately. There are several types of bore gauges commonly used: 1. Telescoping Gauge 2. Inside Micrometer 3. Three Point Bore Gauge Internal Micrometer 4. Bore Gauge Setting Ring 5. Electronic Bore Gauge Each type of bore gauge has its specific applications and advantages depending on the level of precision required and the type of bore being measured.